Award-Winning Chicago Personal Injury Lawyer - Securing Justice

for Illinois Injury Victims - Over $450 Million Recovered

A truck accident involving a poorly serviced commercial motor vehicle tends to unfold fast and end hard, especially when a carrier sends commercial trucks into Chicago traffic with worn braking components, compromised tires, or systems left unchanged after repeated warnings. In these cases, the core problem is negligent maintenance, and the paper trail usually proves it.

Most people picture maintenance as routine oil changes. In truck accident cases, the failures we see are more specific and more dangerous: brake issues from ignored adjustment and replacement intervals, tire blowouts tied to worn tires and underinflation, and suspension systems that were never corrected after inspections flagged defects.

This is how negligent truck maintenance becomes a predictable trigger for serious accidents on expressways, arterials, and industrial corridors. In practice, how negligent maintenance leads to collisions often comes down to one decision: a motor carrier or one of the trucking companies in its orbit chooses to keep a unit on the road rather than take it out of service. That choice increases accident risks. When carriers repeat it across a fleet, it can increase accident risks across the same routes week after week.

A properly maintained tractor-trailer is not “good enough to drive.” It must be kept in a safe condition and a safe operating condition that aligns with manufacturer intervals and internal maintenance guidelines. The expectation is to systematically inspect, repair, and maintain the vehicle on a schedule that reflects regular maintenance, not crisis fixes after something breaks.

That is why we focus on the records and any work orders that show the same defect being “checked” without being fixed. When the documentation reads like a loop, it supports the conclusion that the unit was not properly maintained.

Negligent maintenance cases are winnable because the proof tends to exist in writing. Our job is to gather evidence early, before the records get “cleaned up” or parts disappear. In accidents caused by maintenance issues, the most useful documents usually include:

Our trucking accident lawyers also look for fleet identifiers and tracking details such as a company number on the unit and, when applicable, a serial number tied to a specific component. Those details help trace whether the same part was repeatedly flagged, replaced, or ignored.

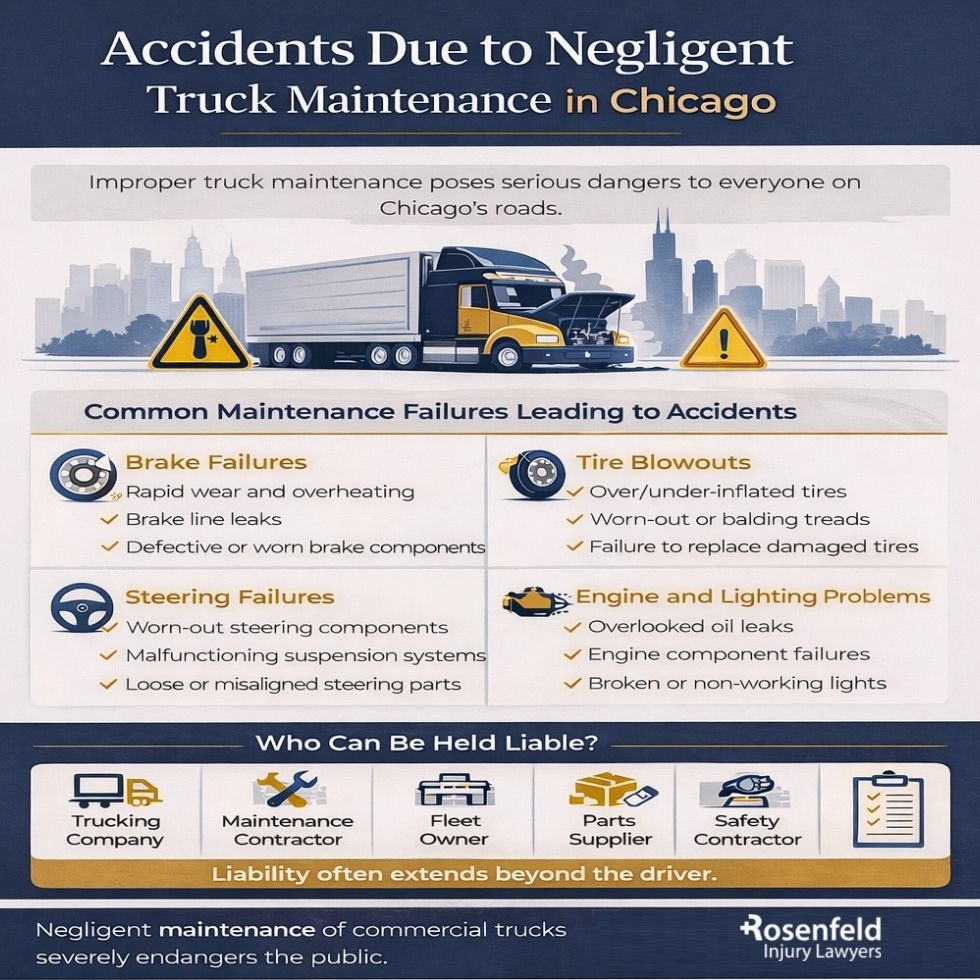

Negligent truck maintenance is rarely abstract. It is physical, mechanical, and usually concentrated in predictable systems.

Brakes are the most common “hidden” failure in a truck accident. Carriers may claim a sudden issue, but brake failureis often the end result of a longer pattern: adjustments skipped, worn components not replaced, air leaks not corrected, and warning signs dismissed.

In a truck accident, brake failure often means the driver cannot slow down in time, cannot control speed on ramps, and cannot avoid impact with passenger cars or other drivers in stop-and-go traffic.

Tire blowouts are frequently tied to worn tires, improper inflation, and low-quality repairs. Once a steer tire fails at speed, the driver may lose control in seconds. That is why negligent truck maintenance cases focus heavily on tire history, replacement intervals, and whether the unit was maintained in line with load and route demands.

Suspension system failures are not just uncomfortable. They change handling, shift weight distribution, and make it harder to keep the vehicle stable in emergency maneuvers. A suspension defect that is left unchanged can turn an ordinary lane correction into a jackknife or rollover scenario.

For certain commercial trucks, emergency doors and related safety mechanisms matter because they affect how people escape after impact and how responders access the scene. When these systems are ignored, the consequences can compound after the collision itself.

Some Chicago crashes involve intermodal equipment pulled from rail yards and chassis pools. When a tractor hauls such equipment, the condition of the chassis and components can become a deciding factor in the accident.

If the failure traces back to an intermodal equipment provider, we investigate whether the intermodal equipment subject provided the necessary maintenance for the equipment to prevent breakdown.

Commercial truck drivers can be pulled into these cases, but the deeper liability often sits with motor carriers and the trucking companies that control maintenance schedules, dispatch decisions, and vendor selection. Many fleets outsource work to a maintenance provider, which can create additional responsible parties when the work was improperly performed or documented.

This matters for truck accident victims because responsibility is not about blaming the person who happened to be behind the wheel. It is about identifying who had the duty to prevent the failure, who had notice of the defect, and who allowed the unit back into service anyway.

A truck accident claim built on improper maintenance is strongest when it is anchored to documentation and physical proof. Our personal injury lawyers focus on:

When that chain is clear, negligent truck maintenance becomes the central liability theme rather than a side argument.

Serious injuries are common in these cases because a mechanical failure often removes the driver’s ability to avoid impact. A commercial truck accident can lead to extensive treatment, time away from work, and long-term functional limits.

The financial picture often includes medical bills, property damage, and lost wages, supported by records rather than estimates. Beyond the economic cost, these cases can also involve emotional distress when a devastating accident changes a person’s daily life.

We pursue fair compensation by building the case around evidence, not assumptions, and by showing exactly how the negligent truck maintenance produced the failure that caused the collision.

Negligent maintenance cases can move fast in the wrong direction if you wait. Parts are swapped, repairs are made, and records get rewritten to look “routine.” That is why our law firm treats the first steps as urgent: secure the unit’s condition, lock down the records, and gather evidence before it is altered.

If you were injured in a truck accident and you suspect negligent maintenance played a role, we can review the facts, identify the likely responsible parties, and explain the next steps. Our personal injury team offers a free consultation so you can understand your options to recover compensation for your medical expenses and lost income.

All content undergoes thorough legal review by experienced attorneys, including Jonathan Rosenfeld. With 25 years of experience in personal injury law and over 100 years of combined legal expertise within our team, we ensure that every article is legally accurate, compliant, and reflects current legal standards.