Award-Winning Chicago Personal Injury Lawyer - Securing Justice

for Illinois Injury Victims - Over $450 Million Recovered

In Chicago’s massive rail yards, truck drivers are often forced to haul rusted, defective chassis. When these trailers fail on I-55, the driver or the logistics giant that owns the gear may be held liable.

CASE AT A GLANCE:

Chicago is the largest rail hub in North America. Every day, shipping containers move from trains to trucks using an intermodal chassis, a skeletal steel frame designed to carry the container on public roads.

The problem is not the concept. It is the condition of the equipment.

Intermodal chassis in Chicago often sit outdoors for months or even years, exposed to mud, snow, road salt, and standing water. Many are more than 15 years old. Maintenance is inconsistent, inspections are rushed, and known defects are frequently ignored.

In most cases, the truck driver does not own the chassis. It is rented from a shared “chassis pool” operated by an Intermodal Equipment Provider (IEP). When a chassis component fails, that IEP becomes a critical defendant. These companies are often overlooked at first, but they control inspection schedules, repairs, and whether defective equipment is placed back into service.

This is why intermodal cases often involve a “ghost defendant”, a company whose name never appears on the police report, but whose negligence caused the crash.

A container does not detach by accident. It detaches because the securement system failed.

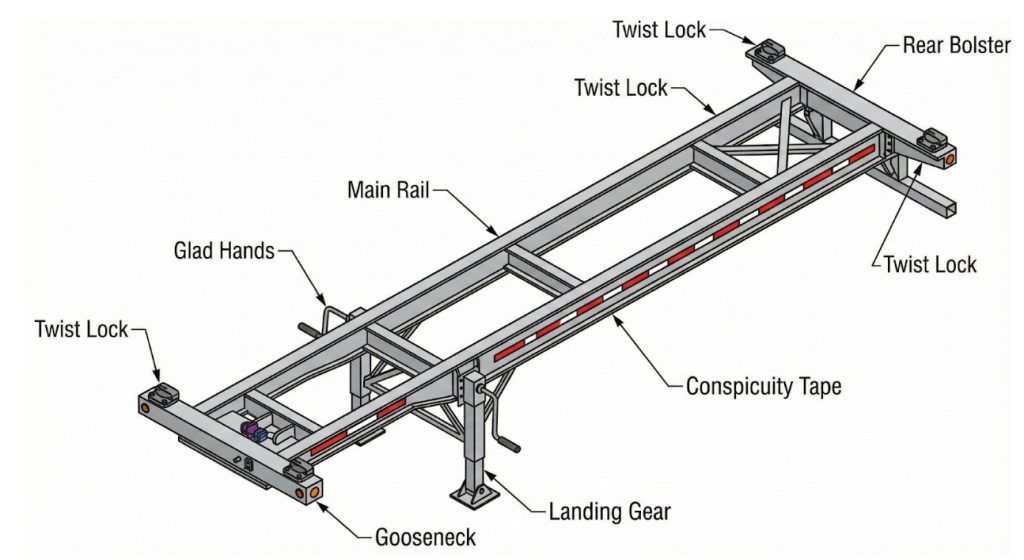

Fig 1.0: The anatomy of an intermodal chassis. Unlike standard trailers, these are skeletal frames that rely on four “twist locks” to secure the cargo container.

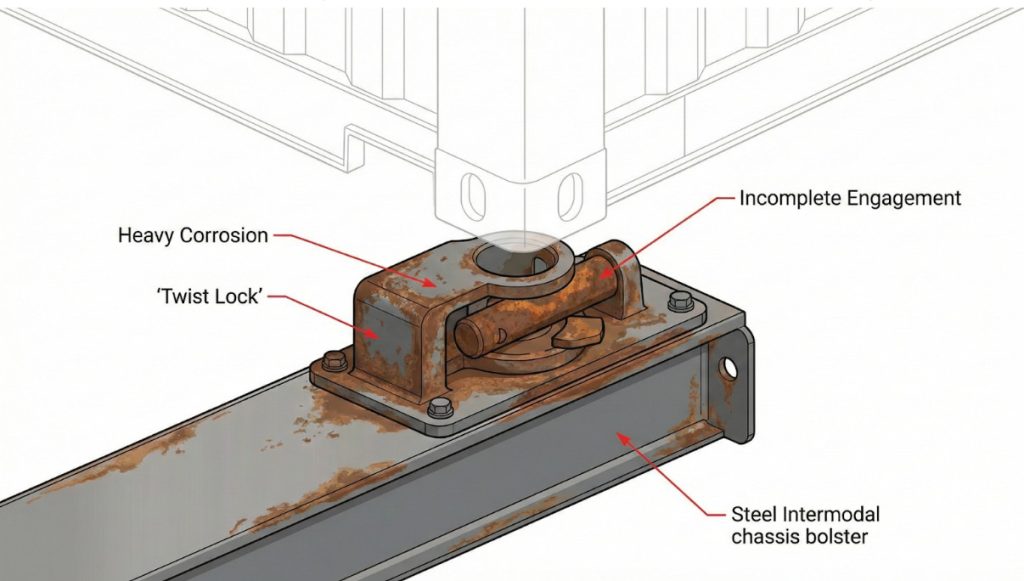

A standard intermodal container is secured to the chassis at four points using twist locks. Each lock rotates into place, mechanically anchoring the container to the frame. When these locks are bent, rusted, or frozen in position (common after years of Chicago winters), they may never fully engage.

Under those conditions, the container is not secured. It is simply resting on the chassis under its own weight.

On curved ramps like the I-55 to I-294 interchange, lateral forces shift the container’s center of gravity. When a container is improperly secured, that shift causes movement. Once the load shifts, the entire rig can roll, or the container can separate completely and enter adjacent lanes.

Police reports often cite “speed” or “driver error.” A proper investigation shows the real cause: securement failure caused by defective chassis hardware.

The following mechanical failures appear repeatedly in our investigations due to the combination of aging equipment and Chicago’s corrosive environment.

Many older intermodal chassis still use bias-ply tires or retreaded tires instead of modern radials. When these tires sit unused in cold conditions, the sidewalls dry out and crack. At highway speeds, the sidewall can fail catastrophically and “unzip” in seconds. A blowout on a lightly braked chassis destabilizes the entire rig.

The twist lock is the single point of failure for container securement. If the locking pin is rusted or the housing is bent, the container is a ticking time bomb.

Skeletal chassis are difficult to see at night. When reflective conspicuity tape is missing, peeled off, or never replaced, the chassis becomes nearly invisible to approaching drivers. Federal regulations require this tape under 49 CFR § 393.11. When it is missing, motorists often do not see the trailer until impact.

Fig 2.1: The twist lock is the only thing holding a 40,000-lb container to the truck. If these locks are rusted or bent, the container can detach on highway curves.

The main rails are the structural spine of the chassis. Years of corrosion from road salt weaken the steel. Under heavy loads exceeding 40,000 pounds, a compromised rail can fracture, causing the chassis to buckle or separate.

Federal law places clear responsibility on Intermodal Equipment Providers.

Under 49 CFR § 390.40, IEPs must establish systematic inspection, repair, and maintenance programs to ensure their equipment is safe for operation. This is known as the Roadability Rule.

Drivers are required to file Driver Vehicle Inspection Reports (DVIRs) when they identify defects. Those reports do not disappear. They create a paper trail.

Our strategy is straightforward: We subpoena the DVIRs. If a chassis was reported with a bad tire, defective twist lock, or structural issue weeks earlier and was rented out again without repair, that is not a mistake. It is evidence of gross negligence.

Intermodal crashes follow predictable geographic patterns. We frequently investigate cases involving equipment originating from popular hubs such as:

If you were struck by a container truck on Arsenal Road, I-55 South, or near these facilities, there is a strong likelihood that the chassis came from a shared pool tied to one of these locations. That connection often determines who is legally responsible for the failure.

Defective equipment is often just one factor in a major collision.

To learn more about how we investigate driver negligence, logbook violations, and trucking company liability, request a consultation with our Chicago Truck Accident Lawyer today.

All content undergoes thorough legal review by experienced attorneys, including Jonathan Rosenfeld. With 25 years of experience in personal injury law and over 100 years of combined legal expertise within our team, we ensure that every article is legally accurate, compliant, and reflects current legal standards.