Award-Winning Chicago Personal Injury Lawyer - Securing Justice

for Illinois Injury Victims - Over $450 Million Recovered

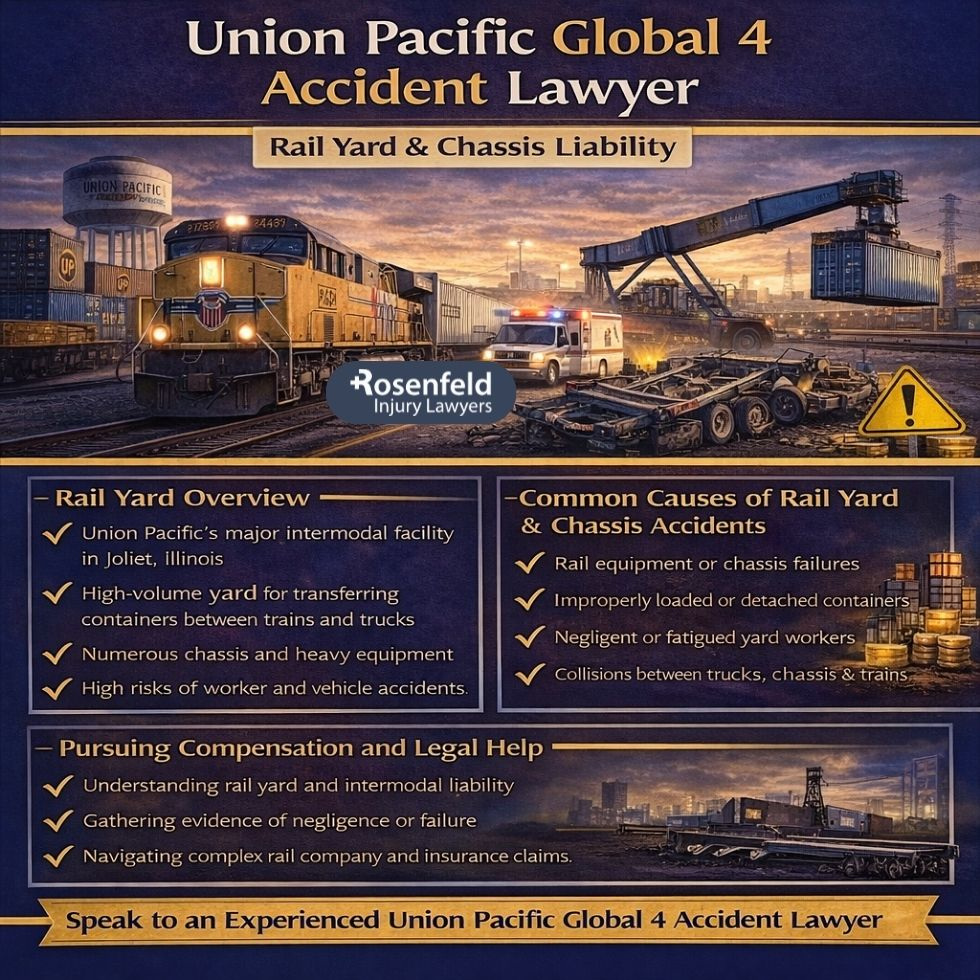

Union Pacific Global 4 is the beating heart of the CenterPoint intermodal system. This is where containers actually leave the train and enter the trucking economy. Once that transfer starts, the risks change. The danger here is not just ordinary roadway negligence. It is mechanical failure, industrial operations, and the controlled chaos of heavy equipment moving in tight spaces.

Global 4 is an industrial zone where trains, cranes, terminal tractors, and semi-trucks all operate at the same time. One wrong move, one equipment defect, or one breakdown in procedures can cause severe injuries.

For drivers, rail workers, and anyone struck by a truck leaving the terminal with unsafe equipment, the legal focus is often the same. Who controlled the yard, who controlled the equipment, and who allowed an unsafe condition to exist?

Intermodal containers do not roll on their own. They move on chassis. And the key legal issue is this: the driver usually does not own the chassis. In many Global 4 moves, the chassis is supplied by an Intermodal Equipment Provider (IEP), often tied to the railroad or a chassis pool.

The law does not treat the chassis as a neutral piece of equipment. The provider has a duty to supply roadable equipment. That means safe brakes, safe tires, safe lights, and a chassis that can be legally and safely pulled on public roads.

When a chassis is defective and a crash happens, the liability picture changes. We do not treat it as only a driver case. We investigate the equipment chain and pursue claims against the provider that put a dangerous chassis into service.

Defective chassis claims often come down to predictable, preventable problems:

These are not mysterious failures. They are maintenance issues. And when they are documented, they can point to the party that had the duty to keep the equipment safe.

If a driver crashes because the chassis failed, the target is not automatically the person behind the wheel. In many cases, the correct defendant is the equipment provider that delivered unsafe gear, and the terminal or railroad operations that allowed the chassis to be dispatched without proper roadability.

That is why early investigation matters. The chassis can be swapped, repaired, or moved out of the yard quickly. Preserving the equipment condition and the interchange records becomes the foundation of the liability case.

Global 4 injuries also happen inside the terminal itself. These cases feel less like highway crashes and more like industrial incidents, with different evidence and different responsible parties.

Terminal tractors, often called yard hustlers, move containers rapidly through tight internal routes. Visibility limitations, blind spots, and speed in confined areas can lead to collisions with:

These cases often turn on traffic control rules inside the terminal and whether procedures were enforced in a way that keeps people safe.

Container operations carry extreme risk. If a crane operator drops or mishandles a container, the consequences are immediate and severe. Injuries can include crush trauma, fractures, head injuries, and catastrophic harm to anyone in the wrong place at the wrong moment.

Liability in these cases can involve operator conduct, training, supervision, and whether the terminal maintained safe lift procedures and safe exclusion zones.

The legal path depends on who was injured. Truck drivers and other non-railroad workers often pursue claims through negligence-based lawsuits against the railroad or third parties. Rail workers may fall under a different system. For many railroad employees, claims can involve federal protections rather than standard workers’ compensation.

The key point is that Global 4 injuries do not fit into a single legal box. A rail employee case and a drayage driver case may involve different laws, different proof requirements, and different strategies, even when the same incident caused harm.

Railroads operating major terminals have responsibilities that extend beyond train operations. When Union Pacific controls yard procedures, staffing, traffic flow, safety rules, and equipment handling inside the terminal, those choices matter. If unsafe conditions are allowed to persist, or if a known equipment problem is ignored, liability can attach to the railroad itself.

That includes safety systems that prevent collisions, procedures that govern container lifts, and the standards used to allow chassis and equipment to leave the terminal.

When a truck driver is injured inside the terminal due to a Union Pacific employee’s actions or because terminal operations created a dangerous condition, the driver may be able to sue Union Pacific directly. These cases often depend on documenting who controlled the area, who controlled the work, and whether the railroad failed to provide a reasonably safe environment.

In practice, that means preserving incident reports, yard camera footage, equipment interchange documents, and the condition of the chassis or container equipment before it disappears into the next move.

Did a defective chassis cause your crash? Were you injured inside the Global 4 terminal? Our Chicago truck accident attorney team knows how to hold the railroad and equipment providers accountable. If you were hurt at Union Pacific Global 4 in Joliet, contact us so a personal injury attorney can identify the responsible entities, preserve the equipment and records, and build the case before the evidence gets moved, repaired, or lost.

All content undergoes thorough legal review by experienced attorneys, including Jonathan Rosenfeld. With 25 years of experience in personal injury law and over 100 years of combined legal expertise within our team, we ensure that every article is legally accurate, compliant, and reflects current legal standards.