Award-Winning Chicago Personal Injury Lawyer - Securing Justice

for Illinois Injury Victims - Over $450 Million Recovered

Loading dock accidents rarely come from one bad moment. They happen inside systems that move fast, involve heavy equipment, and rely on people following routines. A loading dock is controlled until it is not: a trailer shifts, a dock door opens early, a dock plate slips, or a forklift operator hits a gap that should have been blocked.

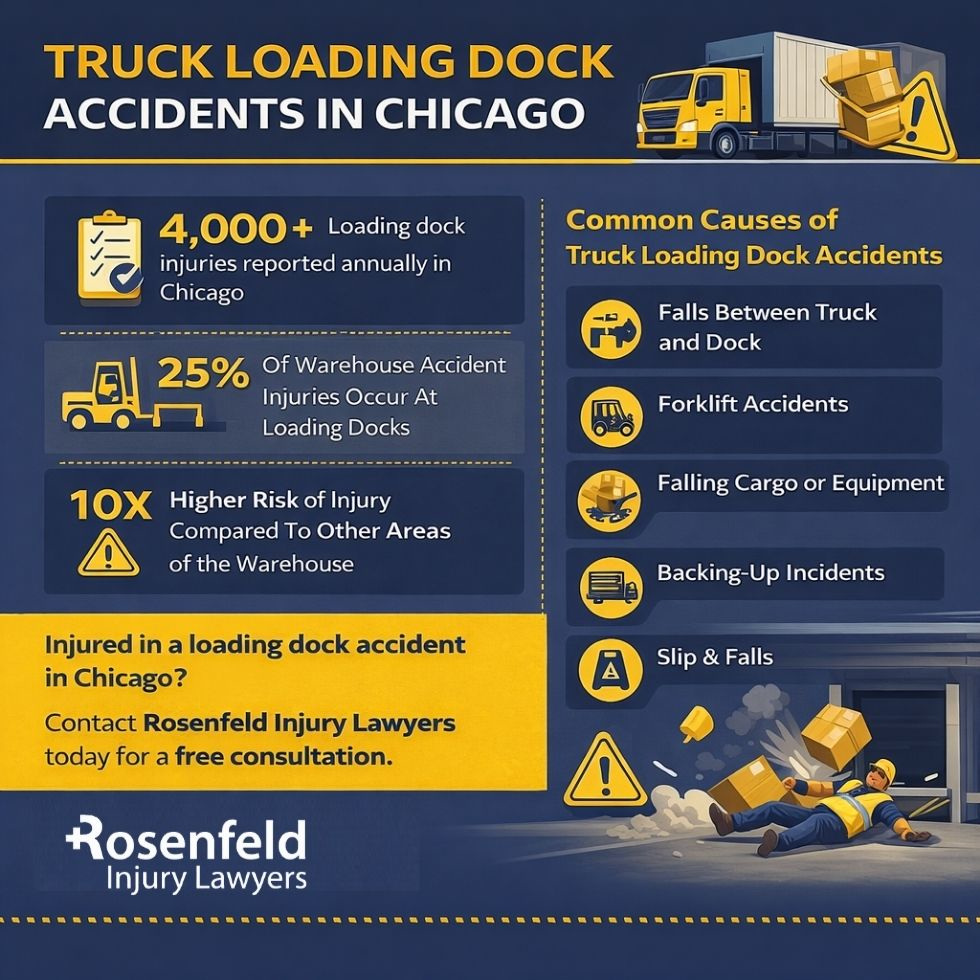

In Chicago-area warehouse corridors and industrial yards, dock accidents can have catastrophic consequences for dock workers, truck drivers, and other workers nearby. When industrial accidents occur at the dock, we focus on the specific failure point, the missed safety measures, and the company decisions that made the dock unsafe.

Loading docks combine moving vehicles, moving equipment, and moving people within a tight footprint. Add changing conditions like congestion, noise, and time pressure, and the dock becomes one of the most dangerous areas in a facility.

The risk increases because doors open and close constantly, forklifts share space with pedestrians, and trailers come and go all day. Many accidents happen during early departure, when a driver pulls out before the unloading process is finished, or when an aggressive pullout happens while workers are still inside the trailer.

Trailer separation accidents are a signature category in loading dock accidents. They occur when a trailer disconnects or moves away from the dock while dock workers or forklift operators are loading or unloading. In the most dangerous versions, the forklift is inside the trailer when the gap opens.

Trailer separation accidents often trace back to:

Trailer separation accidents can also involve trailer pop-up, where the trailer rises as weight shifts during loading, changing the angle of the dock plates and creating a sudden drop. A trailer tip-over is less common, but can happen when the weight distribution changes quickly and the landing gear collapses

Dock levelers and dock plates bridge the gap between the trailer bed and the warehouse floor. When they fail, the injury is often violent and immediate. We look at loading dock equipment condition, alignment, and whether the facility followed inspection practices.

Equipment failures in loading dock accidents include:

Because forklifts cross dock plates repeatedly, small defects become major hazards. If dock safety exists only on paper, the equipment tells the real story.

Dock door procedures matter because doors control access and timing. In many loading dock accidents, doors are opened too early, opened without checking restraint status, or left open while a trailer is not properly secured.

Dock door hazards that lead to dock injuries include:

Doors are not just a building feature. They are part of dock safety and loading dock safety systems, and failures often reflect missing safety measures.

Forklift accidents at the loading dock often happen because the edge is hard to see in motion. Forklifts move fast, cargo blocks visibility, and forklift operators rely on cues that can vanish when conditions change.

Forklift accidents tied to loading and unloading include:

When forklifts are involved, we assess training, traffic patterns, and whether safety barriers or marked exclusion zones were used to protect workers.

Loading dock safety is not a slogan. It is a series of enforced controls. A facility that takes dock safety seriously uses layered safety measures rather than relying on one step.

Measures that help prevent loading dock injuries include:

When loading dock efforts fail, it is often because the facility chose speed over safety or relied on informal training.

Dock accidents spike when the surface changes. Wet weather makes metal plates slick and increases slip risk. Snow tracked into dock environments can melt into puddles and refreeze near dock doors, creating fall hazards.

In these conditions, loading dock injuries become more likely, especially when workers are carrying items, pushing carts, or operating forklifts on a damp transition surface.

Not every loading dock injury comes from impact. Carbon monoxide can build up when powered forklifts or idling trucks operate near closed or partially closed doors. Poor ventilation can expose workers without warning.

In such cases, our Chicago trucking accident lawyers evaluate occupational safety steps, equipment choice, and whether the facility’s safety protocols matched known risk.

Loading dock crashes can involve multiple parties. Depending on what failed, the liable parties may include:

These cases often intersect with warehouse accidents and broader safety expectations inside a facility.

A strong case depends on specific proof. In loading dock incidents, we move quickly to preserve:

Loading dock injuries range from moderate to severe. Serious injuries can come from falls, crushing forces, or forklift accidents. Common injuries include fractures, spinal injuries, head trauma, and internal injuries.

When workplace deaths occur, the investigation becomes urgent and evidence-driven. These are the moments when dock safety either holds up or fails completely.

If you were hurt in loading dock accidents, protect the facts early:

Loading dock crashes move fast, and evidence disappears fast. Early action preserves proof.

If you were injured in a truck loading dock incident, we can review what happened, identify the failure point, and explain your next steps. Our personal injury lawyers offer a free case review for injured truck drivers and other accident victims.

All content undergoes thorough legal review by experienced attorneys, including Jonathan Rosenfeld. With 25 years of experience in personal injury law and over 100 years of combined legal expertise within our team, we ensure that every article is legally accurate, compliant, and reflects current legal standards.