Award-Winning Chicago Personal Injury Lawyer - Securing Justice

for Illinois Injury Victims - Over $450 Million Recovered

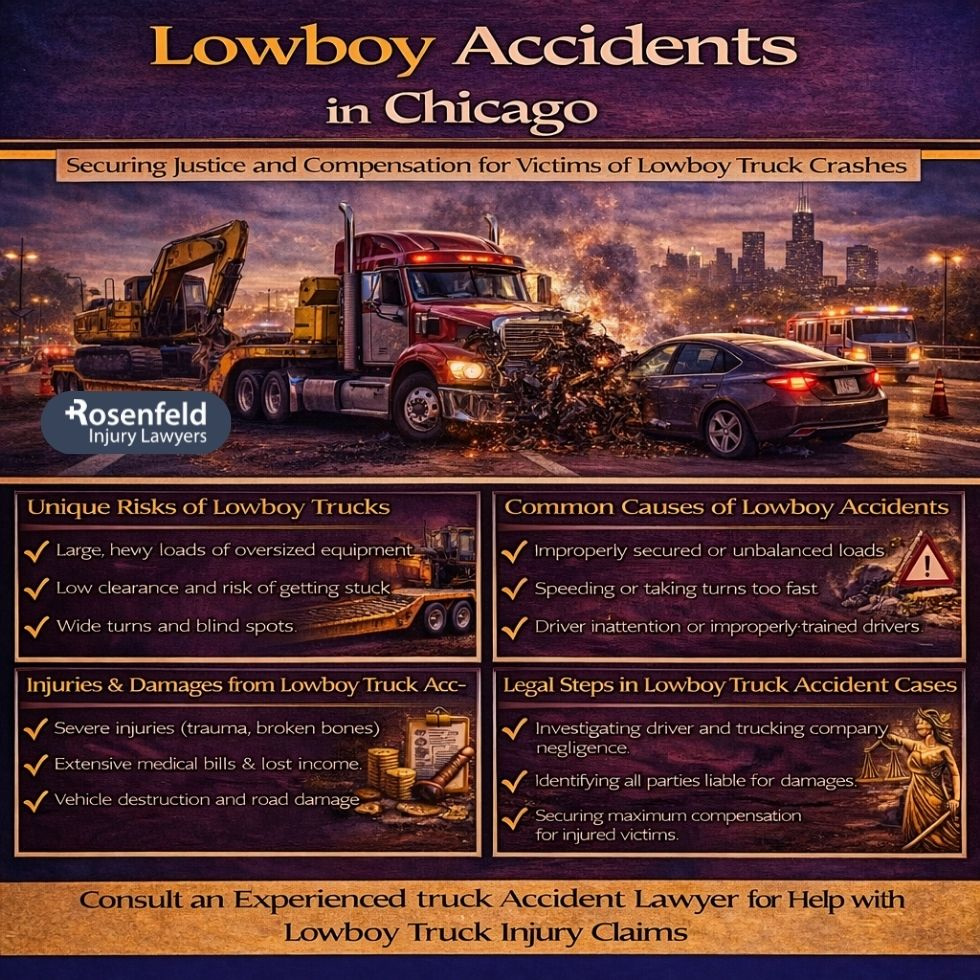

Lowboy accidents are rarely a “routine” truck accident. When lowboy trucks move through Chicago, they are usually carrying heavy cargo that does not belong on ordinary trailers: excavators, scissor lifts, industrial generators, or bulldozers. That cargo sits low to the ground, but the risks are high because the trailer geometry, loading angles, and tie-down mistakes create failure points you do not see in other truck accidents.

A lowboy trailer is built for height clearance, not agility. The deck rides close to the ground, the approach angle is steep, and the ramps become a hazard whenever the driver is loading or unloading near traffic. When something goes wrong, it often goes wrong fast: a load shifts, a ramp slips, equipment falls, or the driver loses control while transitioning from ground to roadway.

Lowboy crashes tend to leave a specific footprint. Instead of focusing only on impact damage, our experienced truck accident attorneys look for what happened during loading and transit that made the trailer dangerous before the collision ever occurred.

Common lowboy truck accident patterns include:

Because lowboy trucks are often tied to construction schedules, we also examine whether the company rushed loading, skipped supervision, or ignored the approved securement plan.

Most lowboy trailer accidents do not begin at the moment of impact. They begin when someone loads equipment incorrectly or chooses a bad surface for unloading.

Loading is not just “drive it up the ramps.” The ramp angle, the equipment’s wheel position, and the contact points on the trailer all matter. When the loading surface is soft, sloped, or uneven, the trailer can shift. When the loader misjudges the center, the cargo can tilt. When the ramps are misaligned, the equipment can slide or roll.

Unloading is just as risky. A lowboy is close to the ground, but the transition from trailer to ground is still steep. If the ground is broken, muddy, or crowned, the equipment can bounce, shift, or roll in a way that sends it into adjacent lanes or into cars parked nearby.

Cargo shift is one of the biggest reasons lowboy trucks cause catastrophic crashes. The trailer can be stable at the yard and unstable on the road. That happens when the tie-downs allow movement, when the equipment is carrying uneven weight, or when the driver brakes hard and the load surges.

A shift can cause:

Even a small movement becomes dangerous because the cargo is heavy and the trailer is narrow relative to what it carries.

Lowboy cases are rarely “driver only” cases. The real liability often sits with whoever touched the load.

Depending on the facts, responsible parties can include:

This is where the case can widen quickly. If the load was secured incorrectly by a yard crew or a contractor insisted on unloading on a surface that was obviously unsafe, the blame can shift beyond the lowboy truck driver.

Lowboy trucks operate in a city environment that does not forgive long turning radii and low ground clearance. The risk rises when the trailer has to navigate uneven pavement, bridge transitions, or construction approaches that were not designed for specialized equipment.

Chicago-area conditions that routinely show up in these cases include:

Even when the driver is trying to operate safely, a lowboy setup can become unstable if the load was not prepared for real-world road vibration.

A lowboy truck accident investigation should be mechanical and procedural, not generic. We focus on the systems that prevent heavy cargo from becoming a projectile.

Key failure points include:

If the evidence shows the cargo was not properly secured, that is not an “accident.” It is a preventable failure.

The strongest lowboy cases are built from physical and logistical evidence that shows the danger existed before the crash.

Evidence that matters most includes:

This evidence helps determine whether the trucking company, cargo loaders, or contractors should be held liable.

Lowboy crashes can create extreme force because the cargo is heavy and sits on an exposed platform. When equipment falls, shifts, or strikes cars, injuries are often serious.

Common injuries in these cases include fractures, crush injuries, head trauma, and multi-system damage. These cases also frequently involve major vehicle destruction because the load does not “give” on impact.

Lowboy crashes are not treated like ordinary truck accidents. Our team identifies every party that touched the load, approved the loading plan, or benefited from rushing the operation. When a lowboy trailer carries dangerous cargo through Chicago, safety is not optional. If a trucking company or loader cut corners, we move to ensure they’re held accountable and pursue the full value of the harm.

If you need an experienced truck accident attorney for lowboy truck crashes, contact us to discuss what happened and what evidence must be secured immediately. Our Chicago personal injury lawyers offer free consultations.

All content undergoes thorough legal review by experienced attorneys, including Jonathan Rosenfeld. With 25 years of experience in personal injury law and over 100 years of combined legal expertise within our team, we ensure that every article is legally accurate, compliant, and reflects current legal standards.